|

B arry's

Tire

Tech This is a series of articles on the technical aspects of tires, their care and usage. My primary purpose in these articles is to help people understand tires and thereby reduce the risks we all face every day. ..........and since tires is just about the only thing I know about.......... Please drop me a note if you have a topic you want to see: Barry@BarrysTireTech.com |

|

Tire Aging and Weather Cracking: What you should get from this page:

|

|

You will hear various recommendations about tire aging: How many years, how bad are the cracks, from date of production or date of install, etc. This page will give you MY recommendations and the justification behind them. They may not be perfect, but at least you will know where they come from. |

|

|

|

|

The reason they word it they way they do is that they know there are a lot of variables and they can not be definitive about a single length of time - and one of those variables is temperature - highly dependent! Did you notice they don't comment at all about weather cracking? That's because there is no consensus between tire manufacturers about how bad is "BAD"! I'll talk about that below. |

|

|

The above was for Passenger and Light Truck (LT) tires. Other types of tires MAY be similar, but I don't know enough to have a strong opinion. EXCEPT: ST tires are in a state of transition (as of the date of this writing - Mar 2022). The recommendation was 5 years max - and that applied everywhere - BUT - recent changes indicate that tire manufacturers (perhaps not all) have stepped up and updated their ST tires, and they MIGHT be performing like P type and LT tires. The jury is still out. |

|

|

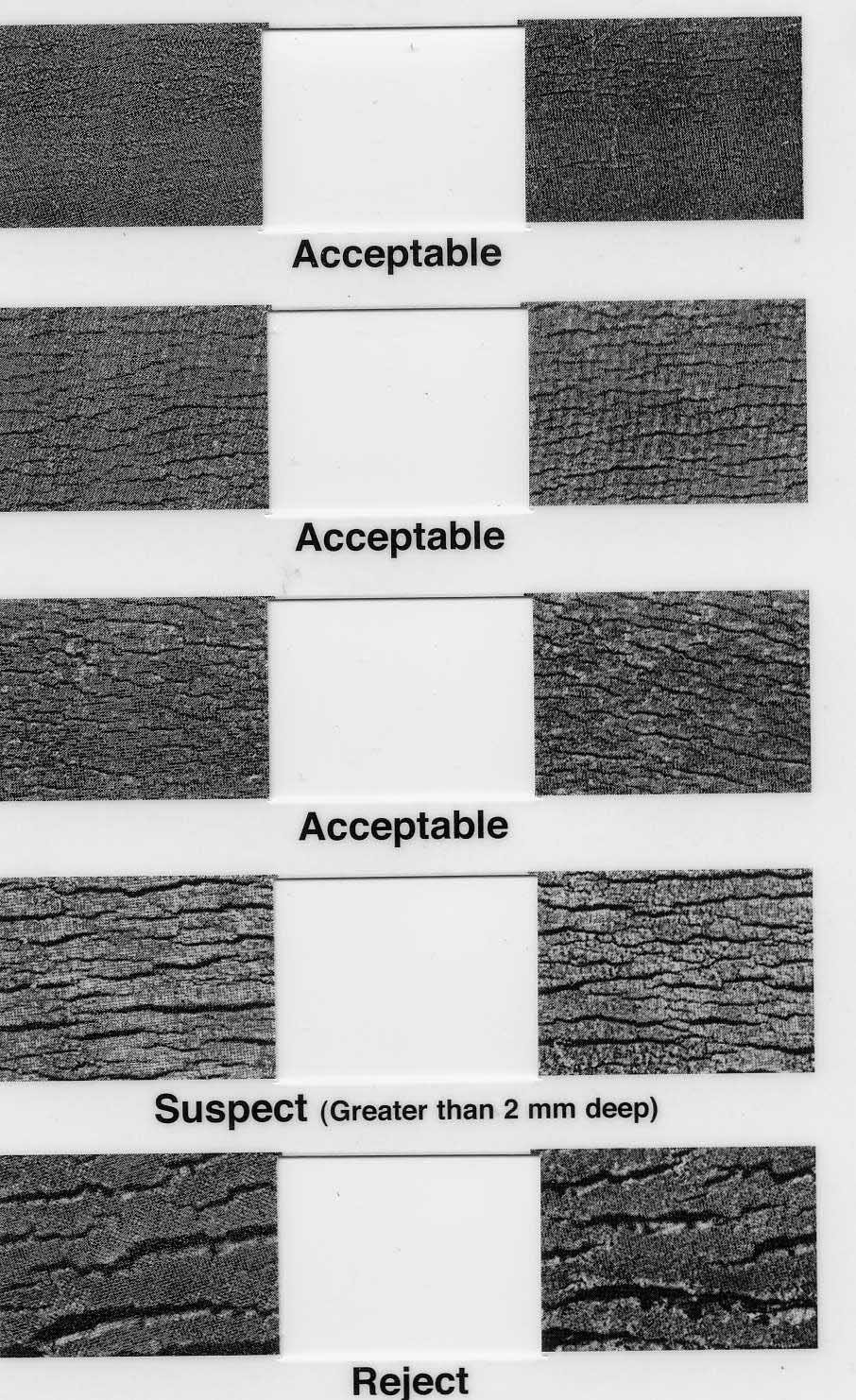

Cracking Cracking is a normal part of the rubber degradation process, so it is the amount and severity of the cracks, NOT the presence of cracks. To the left is a photo of what I consider the point at which removal is warranted. If the cracks are more severe than that, EVEN IF they are less numerous than that, it's over the line. Also, the cracks can appear anywhere on the tire. Note: This is different than what others may say - especially Michelin. I'll explain below. |

|

There is an exception. If the cracks appear on the tread surface and not on the sidewall - like the photo to the right - you need to look in the grooves! That's because the tread surface gets heated and damaged from the heat, and is much more prone to cracking. To determine the real state of the tread rubber, look in the grooves. This is especially true for tires experiencing hard cornering, like Autocross tires. |

|

|

And one thing you need to be aware of: Some tire manufacturers use a crack resistant rubber in the sidewall. They do that to reduce the amount of complaints of sidewall cracking. In those cases, you have to go by the age of the tire - see above. What that means is that cracks = bad, but no cracks does not equal good! |

|

Misc. What about new tires? Tires are built with waxes and antioxidants (AO's) that form a protective barrier. That barrier starts to flake off as soon as the tire is mounted. HOWEVER, it may return, and sometimes in the form of a brown or rust colored film. That is perfectly normal. Most of the tire industry thinks that tires can be considered "New" for up to 6 years after the date of production. I sort of disagree. The company I used to work for tested 3 year old tires and couldn't find a difference with freshly made tires. Admittedly, their storage conditions are good and not everyone stores tires under the best of conditions. So while I subscribe to the 3 year theory, I don't actually know what happens beyond that. |

|

What about the spare? Since the mounting process knocks off most of the waxes and AO's used to protect new tires, spare tires should be considered as though they were in service on the ground- but only lightly used, so they may last longer. |

|

|

What about winter tires or the tires taken off to apply winter tires? Again, lightly used but the clock is still running - albeit more slowly. |

|

What about tire dressings? Tire dressings can do one of 2 things:

|

|

|

The Science:

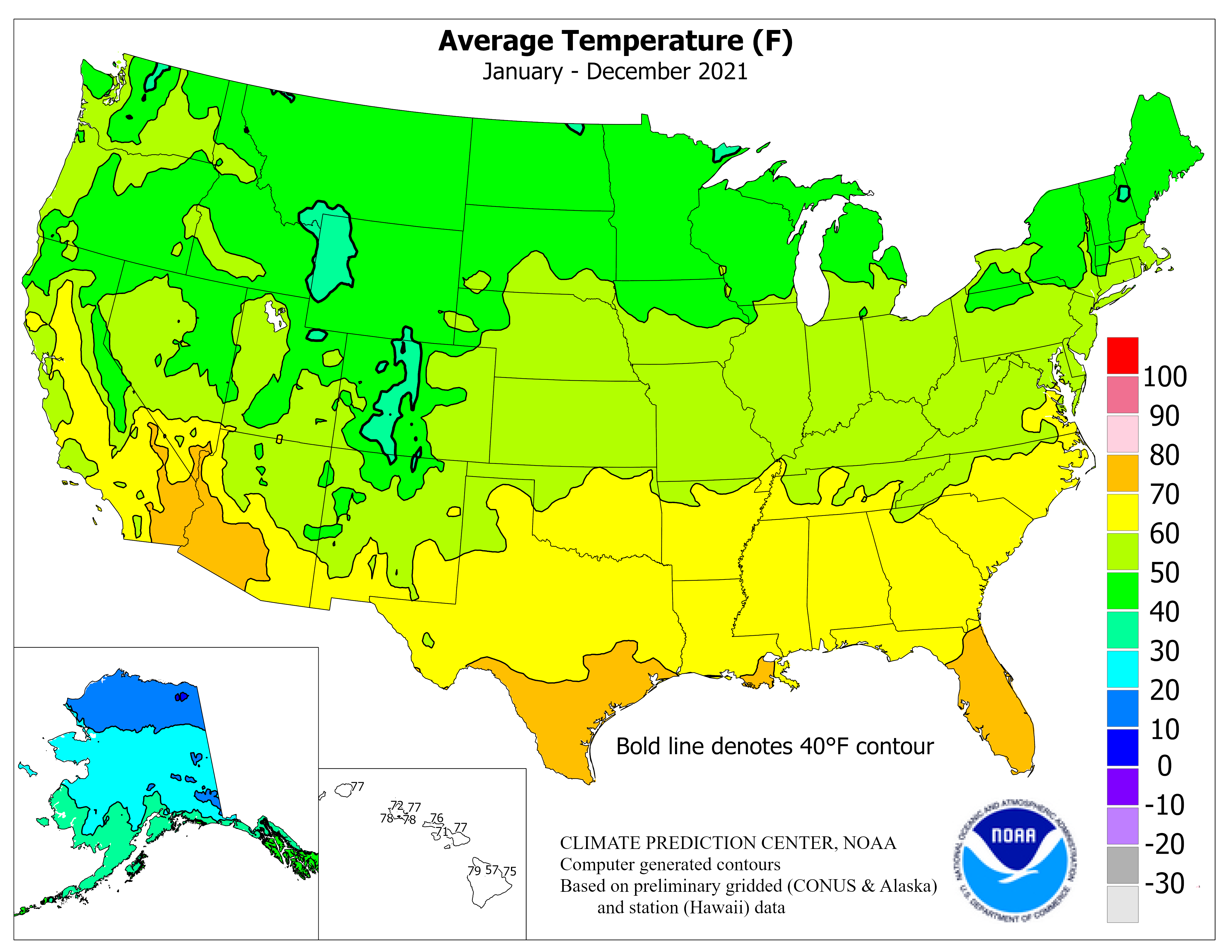

I am not a rubber chemist, but I have worked alongside some very talented ones. Here's what I have picked up: Tire aging is almost exclusively about oxygen attacking the rubber matrix, including the sulfur cross links. It is temperature dependent and antioxidants can only slow down the effect, not eliminate it. To the left is a map of the US with the average temperature for the year 2021. Notice that highest temperatures occur in the desert Southwest - AND Florida! While tire return data is not fine enough to create a map like this, a state by state return pattern shows the same pattern. (Note: I have not found a map on tire returns, and I suspect that is because the data is considered proprietary by the tire manufacturers- so this information wasn't even shared with NHTSA!!) |

|

Some will say: What about UV rays? Aren't UV rays consistent with that temperature map? No, they aren't! See the map to the right. Pay particular attention to Colorado. It's at a higher elevation, so UV rays are stronger - and among the highest in the country, but Colorado does not experience high rates of tire failures - unlike Arizona! Besides, we tire engineers sometimes test tires by Oven Aging them (and that is the term we use) or by inflating them with oxygen, but we NEVER use a UV lamp! |

|

|

Allow me to introduce Svante Arrhenius, the Nobel Prize winning Swedish scientist who came up with - among other things - the Arrhenius equation! Paraphrased: The reaction rate doubles for every 10°C (18°F) rise in temperature. That means that tires in hotter climates are going to suffer more from oxygen degradation than tires in cold climates. |

|

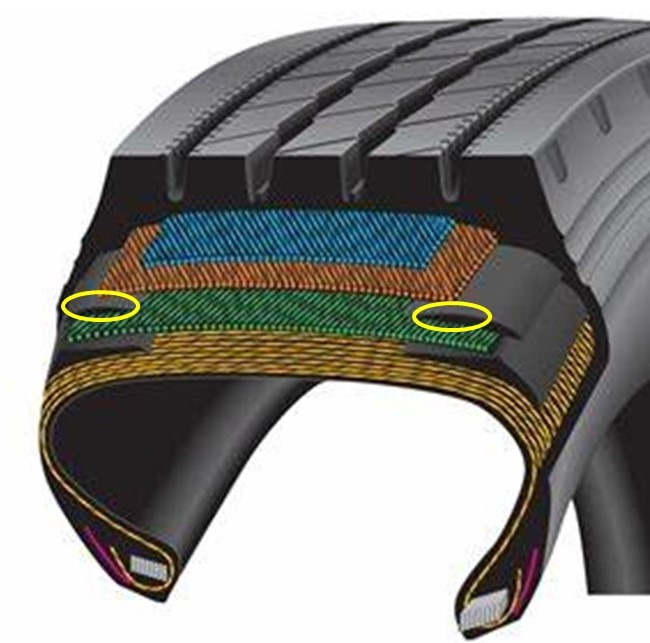

The whole point of this exercise concerns ONLY a certain part of the tire: The rubber insert between the 2 steel belts. The area is circled in yellow in the image to the right. That is where tire failures usually start. It is the condition of that rubber that is important. But there is a problem: Not only is that rubber not exposed to the surface, there is no way to DIRECTLY assess its condition. It is fairly deep inside the tire. But we do have the adjacent surface (Upper Sidewall) and while it is not ideal, it is what we have. Note: Sharp eyed readers will notice that the image is of a Michelin Truck Tire. It has 3 belts and those same readers will wonder why I am not circling the area under that third belt! (the blue one) And that's because in a truck tire (and other larger radial tires), there is usually only 2 "working" belts - the ones that matter in this discussion. The other belts serve a different function - and in this case, it protects the working belts from damage from penetrating objects. |

|

|

There are cracks NOT weather related that one should pay attention to. The next series of photos are samples. Typically, those cracks are individual cracks and not part of the general appearance of the area. If you find cracks like those, seek a tire professional for an evaluation.

|

|

|

|

|

What about antioxidants (AO's)? Don't they slow down the aging process? Apparently not! What they seem to do is protect the surface of the rubber while in storage. My experience is that they seem to have little effect on how long before the oxygen has a significant effect on service life. Waxes and antioxidants are used within the rubber matrix to protect the surface of new tires while in storage. The wax forms a protective layer, while the AO's capture the few oxygen molecules that get through. My experience is that they have little effect on the aging process deep down where it counts AFTER the tires are put into service. You can see the waxes as a white film that forms on the outside of a new installed tire, while the AO's are rust colored (which I assume means they are iron based), both of which flake off fairly quickly after a bit of use. Ya' see, in storage, the waxes and AO's can only migrate a bit- and mostly to the surface, while flexing the tire allows them to move more quickly. So if you don't use the tire very often, it makes the tire more susceptible to cracking. |

|

|

And one last item: Michelin publishes a chart that shows what THEY consider to be the borderline between acceptable and unacceptable cracking. It is to the left. I disagree with it and think they are allowing cracks that are too severe. I think the level just above "Suspect" is the appropriate removal point. In their defense, it is quite possible that the chart is appropriate for THEIR tires. |

|

History: My involvement with tire aging starts about 1990. I joined a newly expanded field engineering department that tested tires on real cars under real conditions. This expansion was done because the tire design engineers became aware of a phenomenon that was taking place in the US desert southwest. Tires were failing, but only after the second summer of service. The failures were different than the lab testing. That area of the country was split up and one of my colleagues volunteered to go live in one of those areas, and another colleague was assigned the other area (he eventually moved there) to get a handle on what was happening. |

|

|

About that time (2000 mid year), the problems Firestone were having with their ATX on the Ford Explorer reached a breaking point. The net result was a HUGE!! recall, lots of questions being asked of NHTSA and tire manufacturers, and Congress passing the TREAD Act. The Tread Act included a provision for the development of a tire aging test. Lots of research was done, including oxygen inflation, but the results didn't correlate to what was found by analyzing the rubber in actual tires where this issue was a problem. |

|

|

Update: Oct, 2022: Many folks are skeptical that tire aging is actually a thing. They point to their experience with an old tire - usually a bias ply tire - as why they don't believe that tire aging is a problem. I am going to start documenting instances where old tires fail - where the failure is obviously due to age. 1) This one is a spare in a 2000 Buick. The tire was never used. You can tell that because the vents are still there. Bob Is the Oil Guy: 2001 Buick 20-year old spare tire... Hard to find! Update Nov, 2023: Above I mentioned tire return patterns - that the pattern was, perhaps, "early failures". I now have an explanation for what was observed: Barry's Tire Tech - Why the Endurance Tire Return Pattern didn't change |